Lead with Swami Engineering Your Trusted Partner in Clean Water Solutions.

Waste Water Treatment Plant (WWTP)

Transform Wastewater into Opportunity with Swami Engineering.

We pioneer comprehensive wastewater solutions as a top-tier manufacturer and supplier. Master every stage under one roof: innovative design, skilled fabrication, rigorous pilot testing, expert erection, and guaranteed commissioning. We create high-performance Sewage Treatment Plants (STPs) for demanding sectors like industry, large communities, hospitality, healthcare, IT, and commerce. Trust our expertise in key technologies: MBBR, SBR, MBR, Soil Bio Filtration, and Electro-Coagulation.

Swami Engineering Services Offering Following Wastewater Treatment Range:

Swami Engineering Services Offering Following Wastewater Treatment Range:

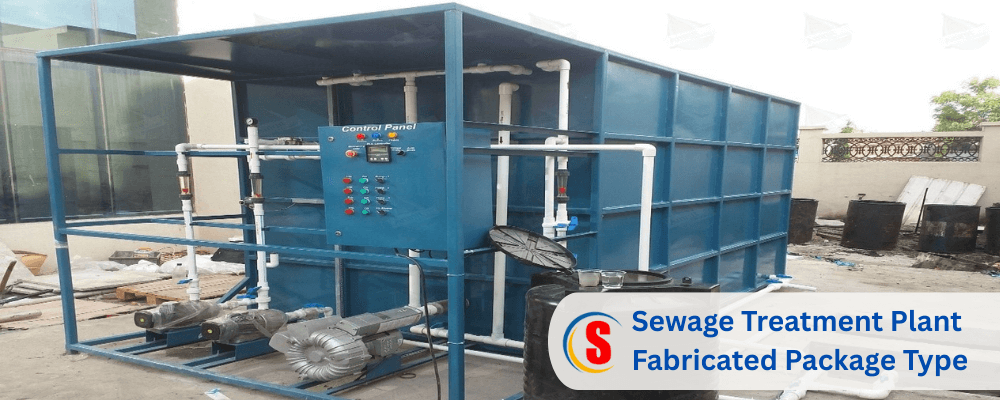

Efficient & Versatile Fabricated Package Sewage Treatment Plant

Scalable Capacity: Perfectly sized solutions from 5 KLD to 500 KLD to match diverse needs.

Advanced Treatment Options: Utilizes proven, efficient technologies (MBBR, SAFF, SBR, MBR) for reliable purification.

User-Friendly Operation: Features convenient semi-automatic control for simplified management.

Effortless Deployment: Designed for easy transportation and swift, straightforward installation.

Expert Commissioning: Erection and start-up handled by our trained and experienced SES team, ensuring optimal performance.

Durable Construction: Tanks built with robust MOC (MS-FRP coated or MSEP) for excellent corrosion resistance and longevity.

Space-Saving & Clean: Completely above-ground installation eliminates extensive excavation and simplifies maintenance access.

Streamlined Civil Work: Requires only the sewage collection tank to be constructed in civil RCC (Reinforced Cement Concrete), minimizing on-site construction.

Ideal Applications: A perfect fit for Medium Scale Industries, Housing Complexes, Labor Camps, and similar developments requiring efficient wastewater treatment.

Sewage Treatment Plant - Civil Type

Broad Operational Capacity: Expertly handles treatment volumes ranging from 10 KLD (Kiloliters per Day) to 10 MLD (Million Liters per Day), catering to diverse community and industrial needs.

Advanced & Efficient Technologies: Utilizes proven, high-performance treatment processes including MBBR, SAFF, SBR, MBR, and ASP, ensuring effective purification.

User-Friendly Semi-Automatic Operation: Designed for ease of use with semi-automatic controls, simplifying daily management.

Minimized Maintenance Requirements: Engineered for reliability, significantly reducing ongoing operational upkeep and costs.

Robust & Adaptable Construction: Built using durable Reinforced Cement Concrete (RCC), offering flexible installation options either underground or above ground to suit site requirements.

Expert Installation & Commissioning: Professionally erected and commissioned by our highly trained and experienced SES team, guaranteeing optimal performance from the start.

Produces Valuable Reusable Water: Generates high-quality treated water perfectly suitable for eco-friendly reuse in irrigation, gardening, and flushing applications.

Ideal for Diverse Applications: Perfectly suited for large residential societies, hospitals, hotels, major industries, and commercial complexes.

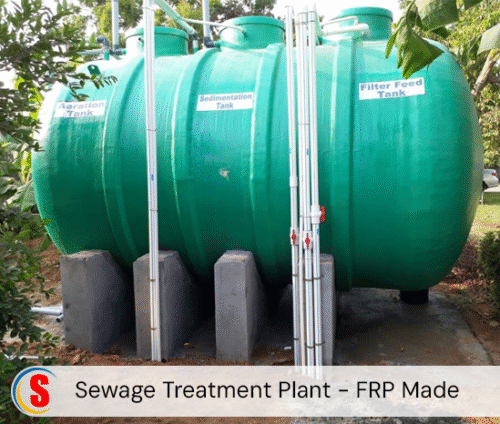

Sewage Treatment Plant – FRP Made Packaged Type

Above Ground Level

Under Ground Installation

✅ Key Features & Benefits:

Versatile Capacity Range:

Efficiently handles 10 KLD to 200 KLD – scalable for diverse needs without compromising performance.Advanced MBBR Technology:

Employs cutting-edge Moving Bed Biofilm Reactor (MBBR) systems for superior wastewater treatment and consistent high-quality output.User-Friendly Operation:

Semi-automatic functionality ensures effortless control while minimizing manual intervention – ideal for hassle-free management.Low-Maintenance Design:

Engineered for minimal upkeep, reducing operational costs and maximizing system longevity.Flexible Installation Options:

Adapts seamlessly to your space constraints with both underground (space-saving) and above-ground (easy-access) configurations.Expert Implementation:

Professionally installed and commissioned by SES’s trained specialists, guaranteeing optimal performance from day one.Sustainable Water Reuse:

Produces treated water perfect for eco-friendly reuse in irrigation, gardening, and flushing – conserving resources and reducing environmental impact.Ideal for Premier Facilities:

Trusted by high-demand sectors like luxury societies, hospitals, hotels, large industries, and commercial complexes for reliable, clean water solutions.

🌟 Perfectly balancing innovation, efficiency, and sustainability for your critical water treatment needs. 🌟

Effluent Treatment Plants

Comprehensive Effluent Treatment Solutions Partner:

End-to-End Expertise: We specialize in the complete lifecycle of Effluent Treatment Plants (ETPs), from innovative design and reliable manufacturing to seamless supply and professional commissioning.

Industry-Wide Application: Our tailored solutions effectively serve diverse sectors including:

Paper & Pulp Industry

Beverage Industry

Textile Industry

Chemical Industry

Pharmaceutical Industry

Food Industry

Hospitality (Hotels)

Automobile Industry

And many others.

Advanced ETP Offerings:

Batch Mode ETP:

Ideal Capacity Range: 1.0 to 20 KLD (perfect for smaller applications).

Effective Technology: Utilizing Physical, Chemical, and Filtration processes.

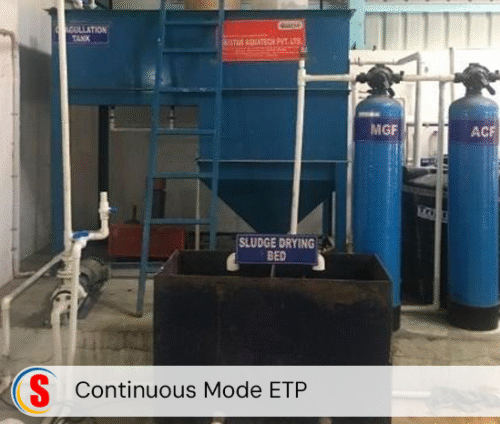

Continuous Mode ETP:

Scalable Capacity: 1.0 to 1000 KLD (handles significant volumes efficiently).

Robust Technology: Relies on Physical, Chemical, and Filtration processes for continuous operation.

Common Effluent Treatment Plant (CETP):

High-Capacity Solution: 20 to 25 MLD (customizable to client needs).

Comprehensive Purification: Combines Physical, Chemical, Biological treatment, and Filtration for thorough organic matter removal and TDS control.

Key Advantages & Features:

Cost-Effective: Lower initial investment requirements.

Space-Saving: Compact, efficient design minimizing footprint.

User-Friendly Operation: Exceptionally quiet running and simple to operate, even by personnel after basic training.

Reliable & Efficient: Semi-automatic operation ensures consistent performance.

Superior Durability: Features MS process tanks with protective internal FRP coating.

Advanced Purification: Incorporates cutting-edge filtration systems (UF, RO) enabling Zero Liquid Discharge (ZLD) goals.

Long-Lasting Infrastructure: Utilizes corrosion-free UPVC piping and FRP/Epoxy lined MS tanks for longevity.

Flexible Construction: Offers both robust MS Fabricated or Civil (RCC) process tank options.

Let’s meet over a coffee

We have a simple vision statement of providing reliable & comprehensive solutions to our clients & in the process grow with the clients to transform itself into an industry leader.